- Home

- Braemac Blog

- Cobots vs. Robots

Cobots vs. Robots

About Jari Haiston

What is a Cobot?

The idea of a cobot sounds like a notion from a science fiction novel, and maybe at one time it was, but industry 4.0 has made the possibility of cobot integration a reality. Collaborative robots are commonly known as cobots and possess the innate ability to work in tandem with humans, whereas traditional industrial robots work in place of humans. While collaborative robots are efficient Industrial IoT (IIoT) solutions, some projects may be better suited for traditional robotic technology. The ultimate considerations of selecting between a cobot or a robot for your automated solution are use case and application.

Key Differences Between Cobots and Robots

Usually taking the form of a fixed robotic arm, cobots aid workers in accomplishing strenuous or tedious tasks. As opposed to traditional robots, cobots have the ability to learn. Cobotic technology offers convenient re-programming as factory workers are able to simply readjust a cobot along its desired track. Cobots will remember their new positioning and repeat the action. In comparison, re-programming a traditional industrial robot involves increased complexity as engineering and new codes are required for any updates to be successfully implemented. Additional differences between cobots and robots include:

- Industrial robots are optimal for heavy manufacturing processes like those of automotive industries due to their inherent ability to handle larger materials.

- Keeping employee safety in mind, industrial robots are equipped with protective cages to separate employees from the workspace and provide a secure environment.

- Cobots are built with customization in mind with pre-engineered designs that can reduce time and cost surrounding tailored applications.

Key Benefits of Industrial Collaborative Robot Integration

According to a 2019 Interactive Analysis study, the cobot market will account for 30% of the total robot market by 2027. The same report also estimates that the collaborative robot market will reach $5.6 billion by 2027. This growth is attributed to the instinctive benefits regarding cobot integration into factories. The evolving collaboration between cobots and people reduces production time and costs. While cobots handle repetitive, physically demanding, or time-consuming projects, factory workers are able to shift their focus onto tasks that better utilize their knowledge and skillset.

Designed to be user-friendly in their programming, setup, and operation, cobots are a flexible IIoT solution. They can improve many different facets of industrial operations with their ability to handle multiple workflows, enhance consistency, and reduce workplace injuries. With the capability of detecting/avoiding obstacles and performing repetitive tasks, cobots help to eliminate repetitive motion injuries and fatigue in factory employees.

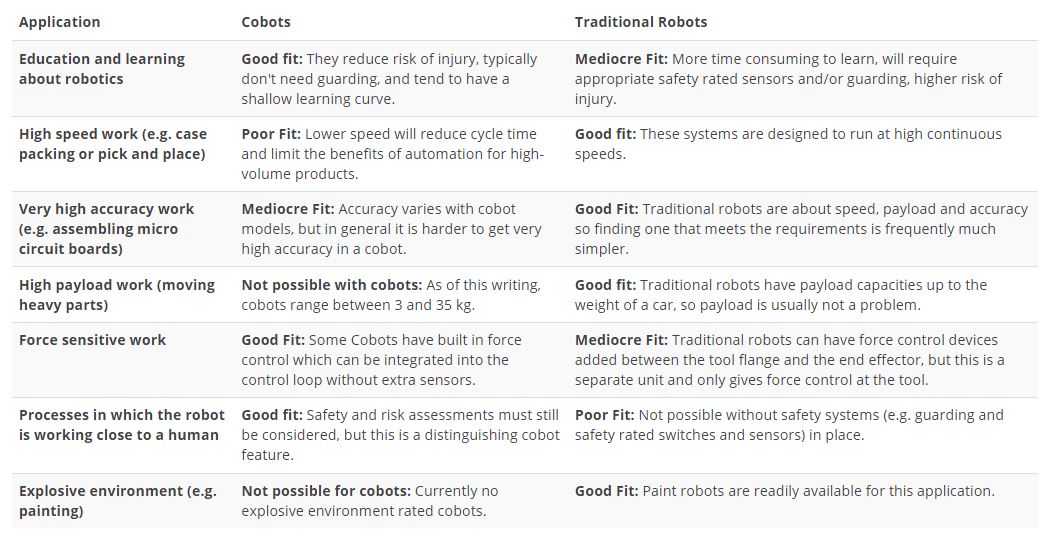

Figure 1: Cobot and Robot Application Comparison

Source: Automation Distribution

Cobot Applications

When determining the optimal technology for your manufacturing process (Figure 1), it’s important to consider the overall use case and application. Cobots are ideal for labor-intensive and repetitive applications, whereas traditional robots are a good fit for high-speed, high-payload situations. Cobots are seeing trends in the following types of applications:

- Automated picking

- Assembly line

- Machine trending

- Packing, packaging, and palletizing

- Materials handling

- Automated replenishment

A common misconception surrounding cobots and robots is that they will completely replace factory employees. While cobots can streamline a wide variety of industrial operations, cobots are intended to work in conjunction with humans. Additionally, traditional robots require an operator. Society must focus on the benefits that automated solution integrations can have in our homes, workplaces, and lives.