- Home

- Symmetry Blog

- DW1000 RTLS Solution in Agricultural Applications

Designing Infrastructure for Tagged Pigs in the Barn: An Introduction to the DecaWave DW1000 RTLS Solution in Agricultural Applications

Friday, August 29, 2014

The Challenges Farmers are Facing Today

As with every other form of production, farming is under continuous pressure to deliver quality product at the lowest possible price. As a result the farmer’s margins are under constant pressure.

To ensure the farmer achieves the maximum possible margin, the efficiency of the farming process needs to be maximized. In the context of dairy cattle this means achieving the maximum output per animal in the most efficient way over the course of its life. In terms of beef cattle, this means achieving the best animal weight and meat quality in the shortest time and for the lowest cost possible.

As the herd grows it becomes more and more difficult for the farmer to individually monitor each animal’s behavior and health. Without the use of monitoring technology and software, a problem with a particular animal may not be noticed until it has reached an advanced stage and requires more dramatic intervention than would have been the case had it been detected earlier.

The 7 Key Areas in Herd Management

- Maintenance of general animal health: The monitoring of the health of each animal in the herd is crucial since each animal represents a considerable investment for the farmer. However, as the herd grows it becomes increasingly difficult to effectively monitor each animal.

- Rumination: Rumination is a part of normal digestion, in which the animal brings up swallowed food, chews it, and swallows it again. This aids the animal by allowing it to eat quickly and chew later while it is resting. By monitoring the animal’s rumination behavior it is possible to detect departures from the norm and thereby take corrective action before a serious problem develops.

- Detection of ill health / disease: There are a lot of common diseases that can be detected earlier by noting changes in animal behavior.

- Ketosis: Detecting ketosis, a metabolic disorder, early in its onset is crucial to farmers. If left untreated, a cow with ketosis will stop lactating within approximately 14 days. Prior to developing the disease cows spend less time eating and may show other behavioral symptoms, including changes in gait.

- Mastitis: Mastitis is an inflammatory reaction of udder tissue to bacterial, chemical, thermal, or mechanical injury, and is the most common disease in dairy herds. It’s been estimated that without an effective mastitis control program, up to 40% of cattle in the herd can be infected in 6 months.

- Milking: It is important that lactating cows are milked at regular intervals. Failure to do so leads to a reduction in lactation rate and a loss of revenue to the farmer.

- Estrous detection: Cows and pigs are known as polyestrous animals, and can go into heat several times a year. The detection of when an animal is in heat is very important to the farmer so that he can make appropriate breeding choices for his herd, including determining when to breed calves for the first time and when cows that have previously calved should be bred again to maintain milk production.

Technical Solutions to Combat the Challenges Faced by Farmers

From the above we can see that up to date information about each animal in the herd is the key to early detection of problems and maximizing output. What is required is a scheme to automatically collect this information, analyze it, and present the results of that analysis to the farmer in a form that allows the farmer to make sensible herd management decisions.

a) Early solutions - not optimum

The first technology to be applied to herd management, driven by regulatory requirements, was that of RFID – by implanting an RFID tag into each animal the movements of that animal through the normal daily processes of eating, drinking, entering and leaving various places on the farm can be logged.

However, RFID has significant drawbacks:

- It can tell us that an animal has passed a particular location at a particular time but it cannot tell us where the animal is now

- It gives us no information about the current state of the animal – its temperature, whether it is lying down / standing up / leaping, etc.

It is a useful first step, but is not the complete picture.

b) DecaWave solution - integrated real time location system

The next step in the evolution of animal management systems is to have continuous real-time information about the location and state of the animal. This necessitates a real time location system.

RTLS implemented for animal management requires high accuracy location and high precision, which can be provided by the DW1000 device.

Example: Tagged Pigs in the Barn Using the DecaWave RTLS Solution

Consider for example that the animal profiling software has determined that one of the tagged pigs in the barn has an elevated temperature and has not presented itself for feeding today. The animal needs to be located, isolated from the remaining animal to avoid possible spread of disease and then treated. To find the animal in a large herd presents a major logistical problem. With accurate RTLS information the location of the animal is known exactly and finding it is not necessary. Similarly with accurate RTLS it is possible to determine whether the animal is standing or lying – this information can be used as part of the profiling process and to detect anomalous behavior.

DecaWave’s DW1000 wireless technology provides the dual capability of accurately determining location (to +/- 10cm) as well as transferring sensor data at high speed so is ideally suited to the implementation of a combined RTLS and wireless sensor network such as is required here.

Implementation of the Infrastructure

There are 3 elements to the infrastructure required to implement a RTLS: tags, anchors, and a location engine.

1. Tags

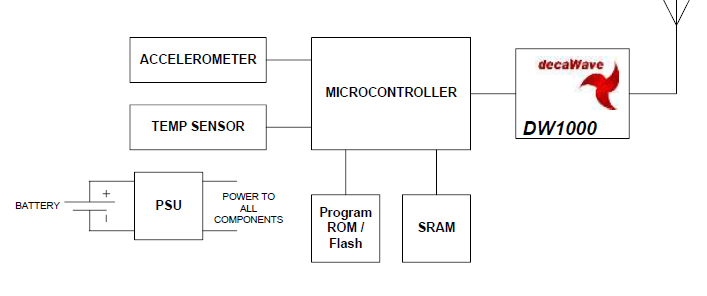

A typical animal tag includes the following subsystems:

- A sensor system to gather data about the animal. The type and number of sensors needed depends on the system requirements, but a temperature sensor should be included.

- A micro-controller subsystem to take the sensor data and interface to the wireless subsystem. The choice of microcontroller as well as the type and amount of memory needed depends on the required level of functionality and the need to minimize power consumption.

- A wireless subsystem to interface to the anchors / communications hubs on the farm – DecaWave’s DW1000 provides a simple interface to a microcontroller allowing a number of different communications schemes to be implemented.

- A power supply subsystem; the complexity of which depends on the type of and voltage range of the batteries being used versus the power supply requirements of individual components.

- An accelerometer detects motion and can be used to control the tag update rate to the location engine. An animal at rest may not need its location updated as frequently as one that is moving. Keeping the update rate as low as possible while meeting all the other system requirements is a key approach to maximizing battery life and minimizing cost of system ownership.

Overall block diagram of a TAG for agriculture use

Overall block diagram of a TAG for agriculture use

2. Anchors

Anchors are mounted around the area in which the farmer wishes to track the animals and receive messages broadcast by the tags. The number of anchors required is a complex trade-off between tag power consumption (higher data rates use less overall power) and the required range between tags and anchors (lower data rates give longer range).

Depending on the RTLS scheme implemented, the anchors will either:

a) Conduct 2-way ranging exchanges with the animal tags to establish the distance between the tag and the anchor, and pass this on to the location engine or;

b) Time-stamp the received message from the tag and pass it on to the location engine. In this case, above all the anchors must be synchronized in time.

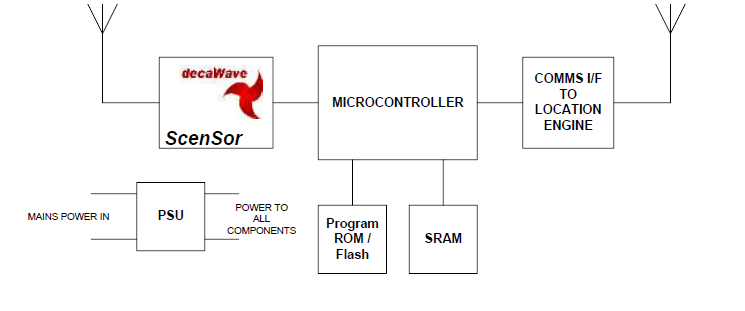

A typical anchor includes the following sub-systems:

- A wireless subsystem to receive the transmitted messages from the animal tags. These messages are time-stamped on arrival at the anchor for location purposes but can also be used to transmit sensor data from the animal tag.

- A micro-controller subsystem to take the time-stamped messages and associated sensor data and relay them to the location engine.

- A communications interface to the location engine. The time-stamped messages need to be communicated to the location engine via some kind of communications interface. There are many ways of doing this but essentially they fall into two categories:

– Wireless connection

– Wired connection

- A power supply subsystem, the complexity of which depends on the type of supply available (batteries / mains power) versus the power supply requirements of individual components.

Block Diagram of an Anchor

Block Diagram of an Anchor

3. Location Engine

A location engine is a software application that runs on a PC or server. It receives time-stamped messages from the anchors. Once it has a sufficient number of time-stamped messages relating to one tag, it processes them to give a location which is usually displayed on a floor plan of the barn or farm area where the animals are located.

In an animal monitoring scheme the location engine is only one component of a complex software suite that:

a) logs individual animal parameters such as temperature, activity levels, location, and so on;

b) builds profiles for each animal;

c) monitors the animals’ parameters for departures from the profile; and

d) provides database facilities for new animals to be entered / sold animals to be deleted.

DecaWave has a demonstration version of a location engine available to customers building an RTLS based on DecaWave silicon.

Interested in setting up your own RTLS scheme? Call Symmetry at (310) 536-6190, or contact us online.